Industrial wastewater treatment technology

Fenton advanced oxidation technology

Technology introduction

Fenton advanced oxidation technology absorbed the advantages of traditional Fenton method in removing refractory organic pollutants and improving the biochemical performance of sewage. Through the control and optimization of various key process links, a new and efficient deep treatment technology for industrial wastewater is formed. Fenton advanced oxidation technology can catalyze the formation of •OH free radicals through the chain reaction between Fe ions and H2O2 after the combination of various agents and sufficient contact. •OH free radicals have strong oxidability and can oxidize various toxic and difficult degradation organic compounds to achieve the purpose of removing pollutants. Under appropriate conditions, COD, chroma, Cr3+ and other pollutants in wastewater can be effectively removed. It is especially suitable for the treatment of organic wastewater which is difficult to be biodegradable or to be effective in general chemical oxidation, such as leather wastewater, dyeing wastewater and leachate.

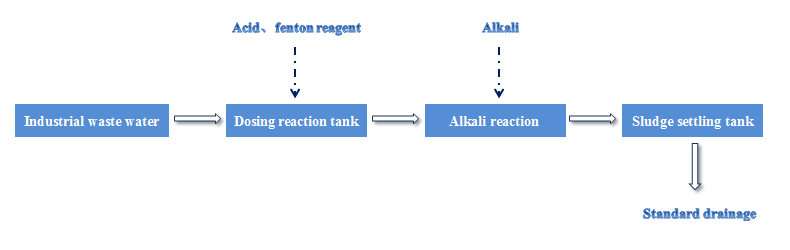

Technological process

Figure 1- Fenton advanced oxidation process flow chart

Technical characteristics

Join Fenton reagent in specific acid environment conditions on the depth of the waste water again after pretreatment processing, senior by Fenton oxidation again after biological treatment of wastewater, the toxicity of refractory organic wastewater, the stronger wastewater and deep oxidation of high chroma waste water treatment, greatly remove the COD and colority in the wastewater and toxicity.

After the chemical treatment in the dosing reaction tank is completed, the pH value in the wastewater is adjusted to the most suitable area for sludge precipitation by adding lye, and the sludge precipitation can be in the best state and achieve the best effect of mud and water separation by adjusting the relevant parameters of the alkali reaction tank.

Technical advantages

As a very effective waste water treatment method, the Fenton advanced oxidation technology can not only improve the biodegradability of waste water in the middle part of the waste water treatment, but also carry out deep treatment at the end of the treatment system. If combined with other conventional treatment technologies, it can achieve the goal of water recycling and recycling. As Fenton advanced oxidation technology has the advantages of small occupation, simple operation, less energy consumption, environmental friendliness and easy solid-liquid separation, it has been gradually applied in various types of industrial wastewater treatment projects, such as leather wastewater treatment, chemical wastewater treatment, medical wastewater treatment and dyeing wastewater treatment.

Integrated automatic depth processing device

Technology introduction

The integrated automatic deep processing device developed by our company can be used for the deep processing of industrial tail water. The main process is coagulation reaction, precipitation, sewage discharge, backwashing, efficient filtration, etc. The integrated full-automatic deep treatment device is added at the end of the industrial waste water treatment system, which can further remove small impurities and SS in tail water after waste water treatment, and realize the functions of zero discharge of industrial waste water and recycling of industrial waste water.

Technical principle and technical features

The treatment of industrial tail water by the integrated automatic deep processing device mainly includes the following processes: coagulation reaction, precipitation, filtration and automatic backwashing.

(1)Coagulation reaction: appropriate agents are added to the inlet end of the integrated full-automatic depth treatment device. Due to the coagulation reaction under the action of agents and unique agitation, the suspended substance and coagulant in the water fully contact reaction to form alum flowers.

(2)Precipitation: the alum flowers formed in the coagulation reaction chamber continue to grow to form large particulate sediments, complete the solid-liquid separation and automatically discharge the mud through electrical control, so as to achieve the purpose of removing the precipitation of industrial tail water pollutants.

(3)Filtering: after precipitation of water gravity filter to filter the storehouse, filter material gradation arrangement was optimized by using stratified, tail water after multilayer filter material of filtering effect to get deep processing, not only make full removal of the SS, but also in the past than industrial tail water some refractory material and toxic materials, etc., and greatly reduce the turbidity of tail water, realize the industrial tail water recycling.

(4)Automatic backflush: after the industrial tail water is collected to a certain extent, the automatic backwash device of the integrated full-automatic depth treatment device will be triggered. After the backwash device discharges the pollutants in the filter silo to the outside, the filter compartment will immediately operate normally.

Equipment advantages

Depth of integrated automatic processing device inside a high concentration of flocculation, can make the impurity in the raw water particles are fully in collision, contact and the effect of adsorption, for all kinds of industrial tail water strong adaptability to the change of water temperature and turbidity of the impurity particles and the removal rate of SS is high, at the same time, automatic backwash device, to ensure the efficient filter and depth of the tail water purification. The integrated full-automatic deep treatment device designed and produced by our company is widely used in boiler wastewater pretreatment, end treatment of dyeing wastewater, deep treatment of leather wastewater and deep treatment of mine wastewater. The application effect of this device has been unanimously recognized by the owner.